Improve higher order rejection of your spectrometer

Continuously Variable Order Sorting Filters for fixed grating mini-spectrometers

Detecting the right wavelength

One of the key applications of our Continuously Variable Edge Filters is as Order Sorting Filter in diffraction grating-based mini-spectrometers.

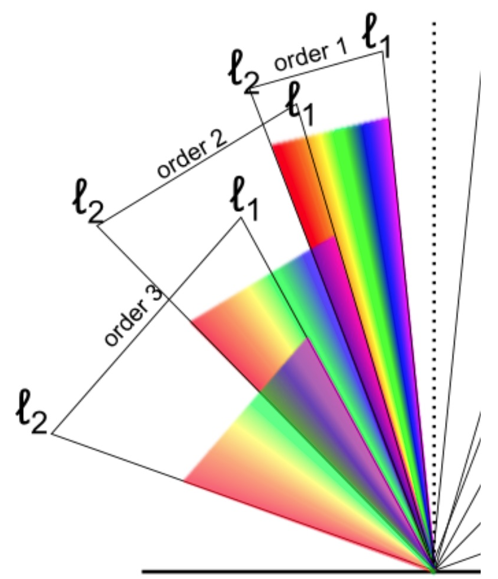

The wavelength dispersive element in most mini-spectrometers is a diffraction grating which separates different wavelengths into different angles – just like a prism that separates white light into a rainbow of colours.

In general, the grating diffracts light at a each wavelength λ into multiple angles – called orders. The diffraction angle of the 1st order of λ coincides with the the 2nd order of λ/2, the third order of λ/3 and so on. Normally, only the 1st order is used and the higher orders need to be removed or ‘sorted out’ before they reach the detector.

For spectrometers that cover less than one octave (ratio of upper to lower wavelength is less than two) this can easily be done by a long wave pass filter with a fixed cut-on wavelength. In this case the cut-on wavelength should just be a little shorter than the lower wavelength of the spectrometer.

Overlapping orders in a spectrometer (source: Ganymede)

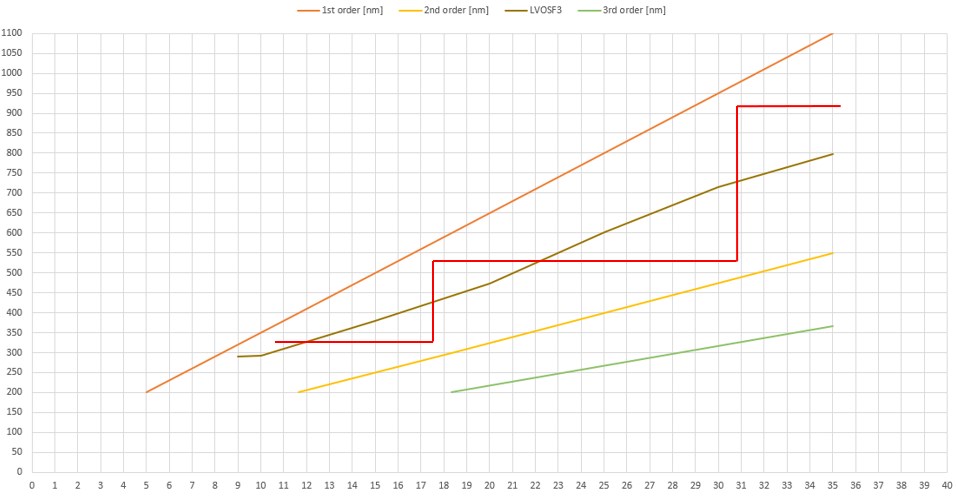

However, when the spectrometer covers more than one octave the orders overlap and a second or third long wave pass filter with a different cut-on wavelength is needed. A typical spectrometer for example that ranges from 190 nm to 1100 nm needs three different order sorting filters.

No matter if these three different filters are mechanically assembled or directly coated onto one substrate there will always be a transition region where the detector will collect meaningless signals.

Suppressing higher orders

Delta Optical Thin Film’s Continuously Variable Order Sorting Filters (CVOSFs) remedy this situation because the coating is continuous and the cut-on wavelength changes continuously along the filter.

Furthermore, a CVOSF suppresses maximum amount of stray light because the cut-on wavelength moves together with the dispersion of the grating.

Comparison of traditional order sorting filter (red curve) and continuously variable order sorting filter (brown curve)

Delta Optical Thin Film’s LVOSF are coated on UV grade fused silica substrates and can be supplied with different dispersions matched to a specific detector and in different sizes. They can be manufactured either with a coating that covers the whole length of the filter or with a section that allows UV light to pass.

Example of un-cut filter specifications

Delta Optical Thin Film can typically customize a CVOSF to your specific spectrometer by dicing a section from one of our raw, uncut filter designs. For inspiration, we have included two examples out of our many uncut filter designs in the table below. Please, contact us to discuss the detailed specifications required for your application.

Principle of a mini-spectrometer

- SMA-connector

- Collimating mirror

- Grating

- Focusing mirror

- Continuously Variable Order Sorting Filter

- Collection lens

- Line scan detector

(Graphic used by courtesy of Avantes)

Watch the video

Remove higher-orders effectively

See how a Continuously Variable Order Sorting Filter effectively removes all higher orders in a diode array spectrometer.